Services

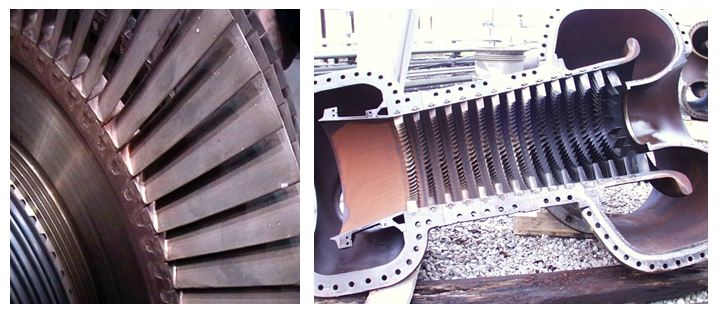

Re-rating turbomachinery

For many years, PCA has been active in the 're-rate' market, both in North America and in Europe, and this has become an important part of our portfolio of operations. Re-rate refers to the re-design of some components of an in-service machine in order to effect a desired change in performance. Often re-rating an older machine can be extremely cost-effective compared to the purchase of a new machine. Re-rate is normally carried out during a routine plant overhaul.

One of the main challenges is to establish the baseline geometry and PCA's expertise in modelling compressors and turbines with 1D and 2D tools is central to this process. Only a few overall performance parameters are normally available during plant operation, so the scope to develop is often assessed without a detailed knowledge of the gaspath. Both turbines and compressors can be re-rated in order to adapt the existing machinery to new site or process conditions. The first level of adjustment may involve only the static components - nozzles or diffuser vanes - but reworking the rotor can maximise the potential. Turbines or expanders normally represent the lowest risk in re-rate projects, power increases of 10 to 15% are typically possible with relatively minor modifications.

Examples of machines re-rated by PCA:

-

five-stage axial nitrogen expander

-

three-stage axial nitrogen expander

-

seventeen-stage steam turbine

-

three-stage condensing steam turbine in a geothermal plant

-

ten-stage axial compressor in a nitric acid plant

-

centrifugal hydrocarbon gas compressor

-

eight-stage steam turbine in an oil field plant

PCA has re-rated several Ingersoll-Rand E-520 axial flow nitrogen expanders in conjunction with Sulzer Turbomachinery Services (Hickham). Mass flow and power increases of at least 10% have been achieved, and at very small additional engineering cost during normal overhaul. E-516 expanders have similarly been re-rated.

An increase in power of 17% for a 17-stage steam turbine was achieved in a re-rate analysis carried out with PCA's 1D and 2D design tools. A 21% increase in power was achieved for a 10-stage steam turbine. Here, CFD was used to optimise the profiles of a new set of blades.